Quality Control

From the procurement of raw materials, processing and production, the selection of partners for important components, to the assembly and commissioning of the whole machine. Each step has a professional quality control personnel real-time tracking inspection. The entire machine production process down a total of 76 quality control procedures.

Service:

24 Hours*7 After-sales Service

"There are 24 hours*7 after-sales service in the head-quarter of our company , If anything wrong with your machine , what you need is call us and we would provide you with timely after-sales service ."

Automation:

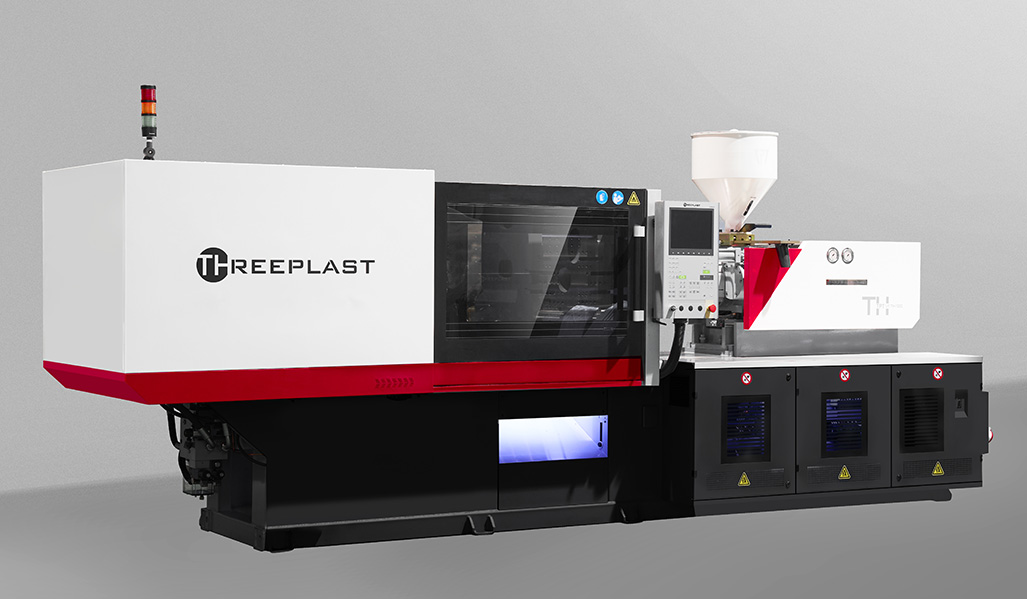

Automated production cells from the system supplier. THREEPLAST combines injection moulding machines, robotic systems and extensive peripherals from renowned partners to create your customised turnkeysystem.

Innovation:

By constantly introducing new materials, processes and design concepts, the machines are able to achieve higher productivity, better quality finished products and more flexible production methods.